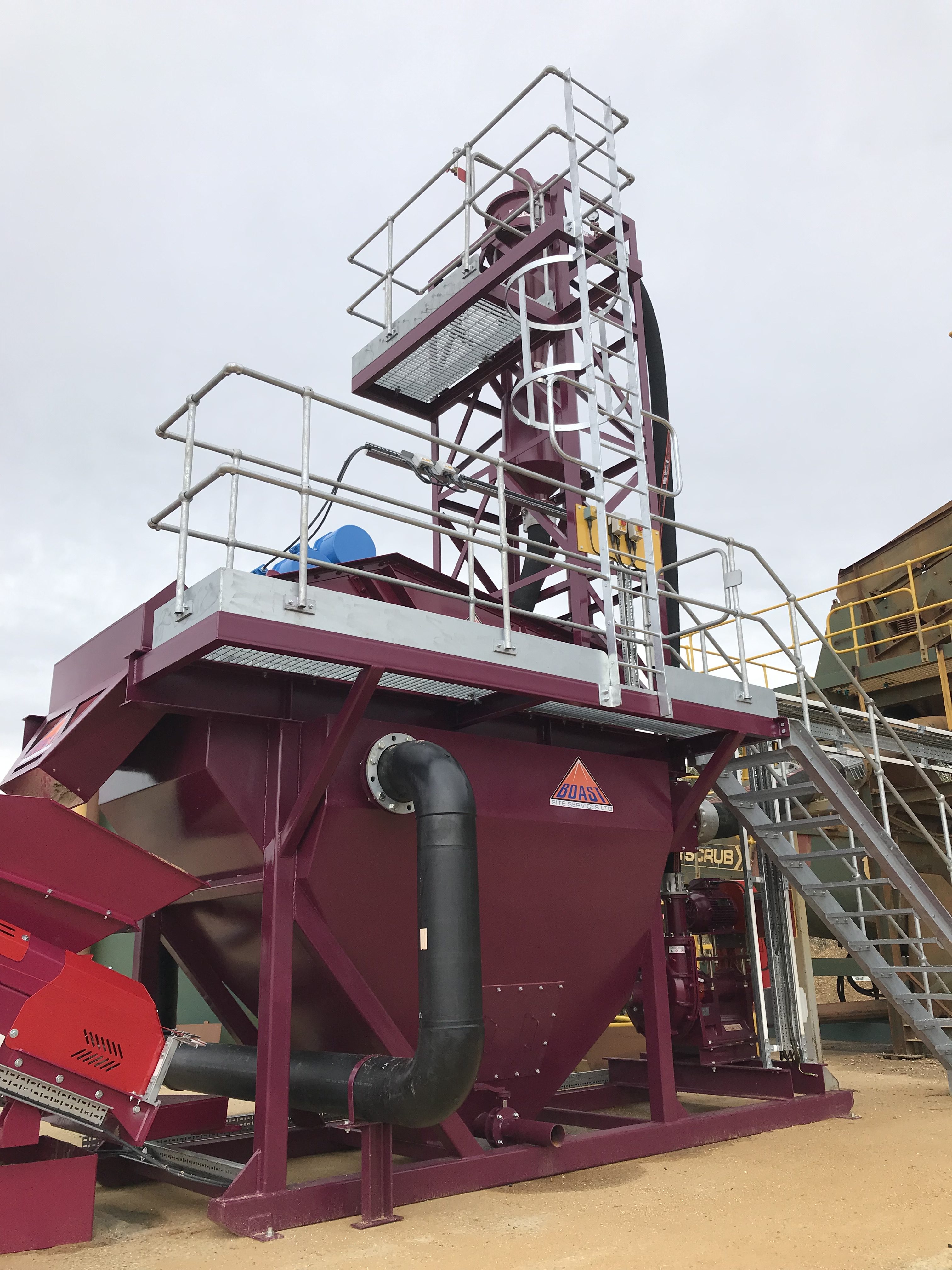

Boast Site Services Ltd have completed the design, manufacture and installation of an upgrade to the typical square sump tank pump arrangement using the industry preferred solution that’s commonly fitted in feed regulating sumps.

The original steel parts are welded in situ and do not facilitate ease of service and replacement. These had to be cut out to enable replacement.

New arrangement incorporates the cast iron suction bend, flexible hose and lined suction pipe to two piece steel pipes with quick release sleeve fitted with Boast SS clamp assemblies.

Read More...